In precision manufacturing, choosing between CNC lathe and CNC milling is critical. Both technologies play essential roles, but their applications, advantages, and suitability differ significantly depending on the project's needs. In this comprehensive article, we'll deeply explore these differences, focusing particularly on CNC milling, a highly versatile machining process widely used across industries.

What is CNC Milling and How Does It Work?

CNC milling is a machining process involving computer-controlled milling machines (CNC milling machine) that remove material from stationary workpieces using rotary cutters. Unlike CNC lathes, where the workpiece rotates, CNC milling machines keep the workpiece stationary while the tool moves around it in various directions. This capability makes milling ideal for complex shapes, custom parts, and precision components.

CNC milling operates through computerized numerical control software, translating design files into precise machine movements. Skilled operators perform CNC milling machine operation by programming the machine based on CAD/CAM software, ensuring accuracy, repeatability, and efficient production runs.

CNC Milling vs. CNC Lathe: Which Should You Choose?

This is one of the most common questions manufacturers ask. The answer depends on your specific production requirements:

CNC Milling is best when:

You need complex parts with intricate geometries.

The project involves a variety of materials, especially metals like CNC milling aluminum.

Customized, small-to-medium batch production is necessary.

CNC Lathe is preferred when:

Producing cylindrical, symmetrical components.

High-volume production runs of similar parts are required.

Simple, rotational parts with high speed and efficiency are the focus.

Understanding your manufacturing goals will greatly simplify this decision-making process.

CNC Milling Advantages: Why It's So Popular?

The popularity of CNC milling is not accidental. Manufacturers choose milling because of several key benefits:

Versatility: Handles various materials such as metals, plastics, and composites effectively. CNC milling aluminum is particularly popular for automotive and aerospace components.

Complexity and Precision: CNC milling produces complex, detailed parts that CNC lathes simply cannot achieve.

Customization: Highly adaptable for prototype development, custom designs, and quick changes during production.

Efficient Operation: Modern machines automate most operations, reducing labor intensity and improving accuracy.

Understanding CNC Milling Machine Price: Is It Worth It?

One frequent search query is "How much does a CNC milling machine cost?" Price varies greatly depending on machine quality, brand, and origin. Choosing a CNC milling machine China is often cost-effective because of competitive pricing combined with reliable performance and advanced technology.

While initial investment can be higher compared to lathes, CNC milling offers broader capabilities that justify its value over time. The versatility and long-term efficiency typically offset the initial costs, particularly for manufacturers prioritizing precision and flexibility.

CNC Milling Aluminum: Best Practices and Advantages

When discussing CNC milling, a commonly searched topic is "CNC milling aluminum." Aluminum is widely preferred due to its lightweight nature, excellent strength-to-weight ratio, and ease of machining. CNC milling aluminum components are crucial in industries like aerospace, automotive, and electronics manufacturing.

Key advantages include:

Fast machining times.

Excellent dimensional stability.

Good thermal and electrical conductivity.

High-quality finishes, ideal for aesthetic parts.

Ensuring optimal tool selection and machine parameters is vital for efficient aluminum milling, which companies like Suzhou Konlida Precision Electronics masterfully handle.

CNC Milling Machine Operation: How Complicated Is It?

A common concern for potential CNC users is, "Is CNC milling machine operation difficult?" Modern CNC milling machines are user-friendly, but achieving optimal results requires skilled operators who understand programming, tooling, and maintenance practices.

Training typically involves learning CAD/CAM software, setup procedures, tooling strategies, and quality control measures. Companies offering CNC milling services, like Konlida Precision Electronics, ensure skilled operators manage production, guaranteeing precision and reliability.

CNC Milling Machine China: Is It Reliable?

Another frequently asked question is about the reliability of CNC milling machine China products. China's CNC machining industry is renowned globally for high-quality manufacturing standards, cost-effectiveness, and technological advancement. Companies like Suzhou Konlida Precision Electronics exemplify this quality, offering precision CNC machining services trusted by international clients across diverse industries.

Applications of CNC Milling in Different Industries

The versatility of CNC milling makes it highly demanded across numerous sectors, including:

Aerospace: For precise, lightweight components critical to aircraft performance.

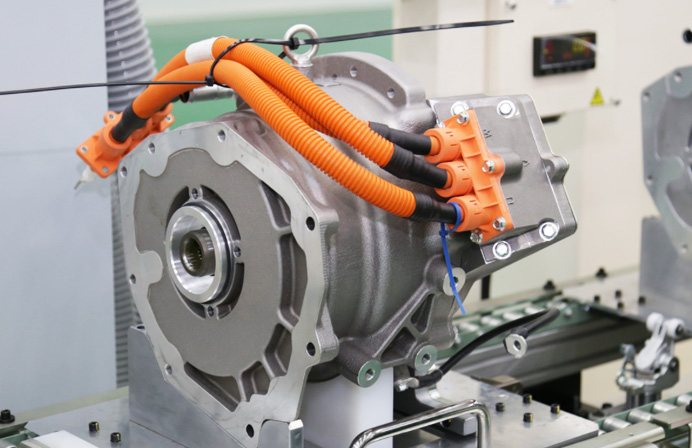

Automotive: Manufacturing engine components, gearboxes, and customized parts.

Electronics: Precision housings, circuit board mounts, and heat sinks.

Medical Industry: Surgical tools, implants, and prosthetic components.

Consumer Goods: Custom designed products requiring detailed machining.

Manufacturers value CNC milling for its capability to consistently produce highly precise and customized parts tailored to industry-specific needs.

Tips for Choosing a CNC Milling Service Provider

When outsourcing CNC milling, selecting the right service provider is crucial. Consider factors like:

Industry experience and track record.

Quality certifications such as ISO9001 and AS9100D.

Ability to handle diverse materials and surface treatments.

Responsiveness and after-sales support.

Proven quality control and inspection processes.

Suzhou Konlida Precision Electronics meets all these criteria, delivering top-quality CNC milling services with a strong customer satisfaction record.

FAQs about CNC Milling

Q1: What is CNC milling commonly used for?

A1: CNC milling is commonly used to create complex and precise components in industries like aerospace, automotive, medical, and electronics.

Q2: Can CNC milling machines process aluminum?

A2: Yes, CNC milling machines efficiently process aluminum, offering fast machining speeds, excellent finishes, and precision for various applications.

Q3: Is CNC milling expensive compared to CNC lathe?

A3: Initial costs for CNC milling machines can be higher than CNC lathes, but milling offers greater flexibility, complexity handling, and long-term value.

Q4: How to choose between CNC milling and CNC lathe?

A4: Choose CNC milling for complex parts, prototypes, and customization, and CNC lathe for high-volume production of cylindrical components.

Q5: Are CNC milling machines from China reliable?

A5: Yes, CNC milling machines from China, especially from reputable companies, offer high reliability, advanced technology, and cost-effectiveness.

Q6: What skills are required for CNC milling operation?

A6: Operators need knowledge of CAD/CAM software, tooling setups, CNC programming, and machine maintenance for successful CNC milling operation.

CNC Milling or CNC Lathe, Which is Superior?

The decision between CNC milling and CNC lathe ultimately depends on your specific manufacturing needs. CNC milling is superior in versatility, complexity handling, and customization capabilities, making it suitable for manufacturers needing detailed, precise, and complex parts.

Companies like Suzhou Konlida Precision Electronics demonstrate CNC milling’s strengths through advanced capabilities, high-quality products, and strong international credibility. Understanding your project's specific requirements, industry standards, and precision demands will guide you toward making the best decision between these two essential machining technologies.