Reliable on-demand CNC milling services for rapid prototypes and production parts. Get top-notch custom milled parts from various high-quality metals and plastics at competitive prices.

Tight Tolerance of 0.01 mm

Milled Parts as Fast as 1 Day

3, 4, 5 Axis Milling

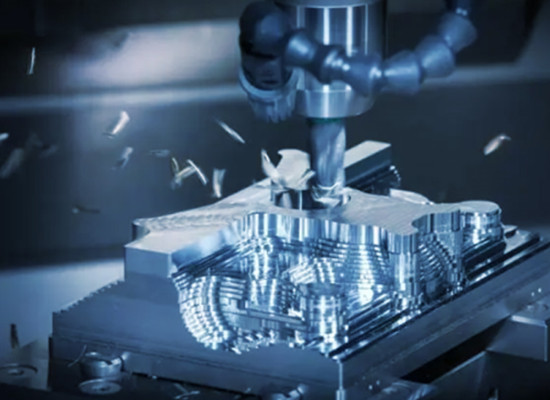

CNC milling is a machine tool processing method that uses computer programs to control the movement of milling cutters for part processing. It can achieve high-precision and high-efficiency processing, especially suitable for processing large quantities of complex shaped parts. Powerful CNC milling services include advanced machining technology, multiple material processing capabilities,Automated processing capability, processing flexibility, and fast processing speed are suitable for mass production.

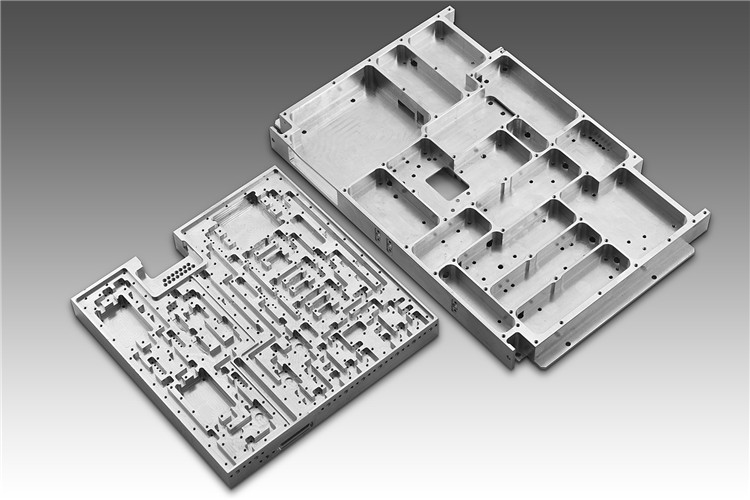

3 Axis CNC Milling

Three-axis CNC milling is a CNC machining technology that can achieve high-precision milling. It mainly consists of three axes, namely the X axis, the Y axis, and the Z axis. The motion control of these three axes is controlled by a numerical control system, which can perform high-precision planar and curved surface machining on the workpiece.

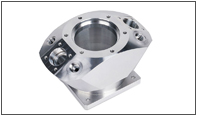

4 Axis CNC Milling

4-axis CNC milling is a machine tool control technology used for precise machining of complex parts. It completes the machining of the workpiece by controlling the four axes of the machine tool (usually x, y, z, u, v). The 4-axis CNC milling technology has the advantages of high precision, high efficiency, and high stability.

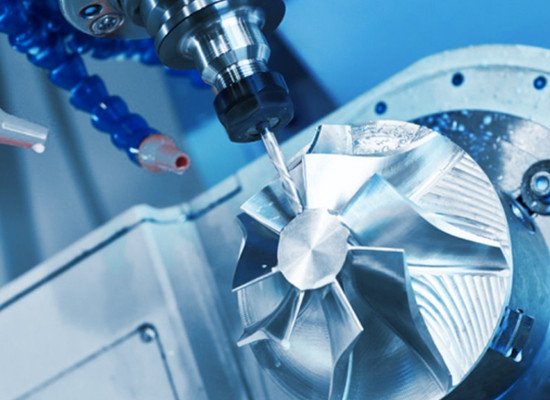

5 Axis CNC Milling

Compared with traditional 3-axis CNC machining, 5-axis CNC machining can more accurately control the motion trajectory of the tool, thereby improving machining accuracy and efficiency. 5-axis CNC machining is commonly used for high-precision molds, complex parts, and other fields of processing.

At Konlida, we are committed to helping you reach your manufacturing goals. We constantly strive for effective solutions through our progressive technological approaches and machining techniques. Our CNC milling services ensure you get highly precise prototypes and production parts with superior quality.

| Milled Parts with Tight Tolerances We implement strict quality management to ensure consistent high quality on your CNC milled parts. Provide full-dimensional and material inspection reports on your request. With strong CNC milling capabilities and technological implementations, all of your customized CNC milling parts will meet the accuracy requirements. |

| Fast Lead Time Not only do we have a digital CNC machining services platform that provides faster ordering process, we also own domestic workshops and state-of-the-art machinery to accelerate the production of your prototypes or parts. |

| 24/7 Engineering Support No matter where you are, you can get our 24/7 engeering support all year around. Our experienced engineer can provide you with the most appropriate solution to your part design, material selection, and surface finishing options and even lead time. |

CNC machining is a computerized and versatile manufacturing process ideal for rapid prototyping and on demand production. Here are the custom CNC services available at the Konlida.

Rapid Prototyping

With our strong production and delivery capabilities, we can quickly create and shape products in a short period of time, enabling your products to quickly enter the market.

Konlida offers a range of CNC machining tolerances to suit your unique design requirements.

Type | Tolerance |

Linear dimension | +/- 0.025 mm +/- 0.001 inch |

Hole diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch |

Shaft diameters | +/- 0.025 mm +/- 0.001 inch |

Part size limit | 950 * 550 * 480 mm 37.0 * 21.5 * 18.5 inch |

Aluminum Copper Brass Stainless Titanium

| Aluminum Alloy Material:Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications. | Alloys:6061-T6, 7075-T6, 7050, 2024, 5052, 6063, MIC6 Finishing Options: Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing. |

| Stainless Steel Material:Stainless steel is highly resistant to corrosion and rust, making it suitable for situations where a part may be exposed to the elements for long period of time. Stainless steel is also fairly malleable and ductile. | Alloys:303, 304L, 316L, 410, 416, 440C, 17-4PH, Nitronic 60. Finishing Options: Black Oxide, Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Zinc Plating, Vibratory Tumbling |

| Stainless Steel Material:101 and 110 copper alloys offer excellent thermal and electrical conductivity, which makes them natural choices for bus bars, wire connectors, and other electrical applications. | Alloys:T2、T3、101, 110Finishing Options: Available as-machined, media blasted, or hand-polished |

| Titanium Alloy Material:Titanium may be selected over other materials such as steel due to its ability to withstand high and subzero temperatures. Common use cases include aerospace fasteners, turbine blades, engine components, sports equipment and marine applications. | Grade:Grade 2、Grade 5 Finishing options: Media Blasting, Vibratory Tumbling, Passivation, Powdercoating |

| Non-Metallic Materials:Plastics are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services. | POM、PEEK、HDPE、PET、Nylon、PTFE、PVC、PP、ABS、PC、PMMA. |

| Picture | Name | Applicable Materials | Colors | Can be applied with |

| Anodizing | Aluminum | Clesr, black, grey, red, blue, gold | Media Blasting, Tumbling, Alodine |

| Black Oxide | Steel, Stainless Steel | Black | Media Blasting, Tumbling, Passivation |

| Electroless Nickel Plating | Aluminum | Customizable | Media Blasting, Tumbling, Passivation |

| Electropolishing | Steel, Stainless Steel | Customizable | Media Blasting, Tumbling, Passivation |

| Hand Polishing | Acrylic | Customizable | Enhanced cosmetic appearance |

| Media Blasting | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | Customizable | All post processes except Electropolish and Powdercoat |

| Powder Coating | Aluminum, Steel, Stainless Steel | Customizable | Media Blasting, Tumbling |

| Zinc Plating | Steel, Stainless Steel | Clear: light blue coating Black: glossy black coating | Media Blasting, Tumbling, Passivation |