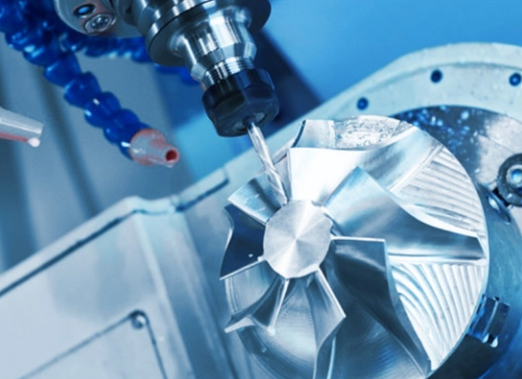

When it comes to manufacturing high-precision components, CNC machining remains the gold standard. Whether you're designing intricate gears, custom mechanical assemblies, or essential industrial parts, understanding how to design parts for CNC machining is crucial to achieving the best results. In this comprehensive guide, we will explore everything you need to know about CNC Machining Parts, including expert tips on designing for manufacturability, material selection, cost-saving strategies, and how to work with a reliable CNC machining parts manufacturer in China like Suzhou Konlida Precision Electronics Co., Ltd.

Suzhou Konlida, established in 2006 in Suzhou, China, is a leading expert in the field, offering custom CNC machining service, aluminum CNC machining service, Stainless Steel CNC machining services, and much more. With ISO9001 and AS9100D certifications, a 25,000 factory, and 18+ years of experience, Konlida delivers superior CNC Machining Services across industries such as medical, semiconductor, automotive, and aerospace.

CNC Machining Parts are the backbone of modern manufacturing. Precision, durability, and functionality largely depend on how well the parts are designed. A well-thought-out CNC Machining Parts drawing reduces production errors, shortens lead times, and saves costs, ultimately enhancing the final product's performance.

At Konlida, our engineering team reviews every CNC Machining Parts drawing meticulously to ensure manufacturability and optimize performance. Our customers benefit from expert custom CNC machining service whether they need small prototyping batches or mass production.

Before starting a CNC Machining Parts design, it's important to understand CNC machining technology:

| Process | Description | Applications |

|---|---|---|

| CNC Milling | Uses rotary cutters to remove material | Complex 3D shapes, pockets, slots |

| CNC Turning | Rotates the material against a cutting tool | Cylindrical parts like shafts, pins |

| CNC Drilling | Creates round holes | Fastening features, mounting holes |

| Laser Cutting | High precision cutting with lasers | Sheet metal parts |

| 3D Printing | Additive manufacturing for prototypes | Rapid prototyping |

At Suzhou Konlida, we utilize advanced equipment such as DMG 5-axis CNC machining centers and Swiss-type lathes, ensuring the production of high-precision CNC Precision Machining Parts with tolerances as tight as 0.001mm.

When designing CNC machined parts and components, following best practices ensures optimal results:

Complex geometries increase machining time and cost. Try to design parts with simple shapes, fewer deep cavities, and minimal undercuts.

Specify tight tolerances only where necessary. Over-specifying precision can significantly increase costs. At Konlida, standard tolerances for CNC Machining Services are ±0.01mm.

Material selection affects machinability and part performance:

| Material | Properties | Common Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Aerospace, automotive |

| Stainless Steel | Strong, corrosion-resistant | Medical, food industry |

| Titanium | High strength-to-weight ratio | Aerospace, medical implants |

| Plastics (PEEK, ABS) | Lightweight, chemical-resistant | Electronics, medical devices |

Konlida offers Aluminum CNC Machining Service, Stainless Steel CNC Machining Services, and machining of titanium, copper alloys, and engineering plastics.

Ensure all features are accessible to cutting tools. Avoid deep, narrow slots or inaccessible internal cavities.

Parts that require multiple setups are more expensive. Design parts that can be machined in fewer setups whenever possible.

Working with an experienced CNC Machining Parts manufacturer in China like Konlida provides significant advantages:

24h quotation and consultation

3-day lead time for prototypes

MOQ as low as 10 pcs

Export qualifications to the USA, Europe, Japan, and more

Expertise in medical, semiconductor, automation, and optical industries

Our Online CNC Machining Service allows you to upload your CNC Machining Parts drawing and get a rapid quote, making it easier than ever to start your project.

Designing features that are too small for available tool sizes

Overcomplicating parts with unnecessary details

Ignoring material limitations

Failing to account for thermal expansion

Misaligning tolerances between mating parts

Suzhou Konlida’s expert team reviews every CNC Machining Part design to avoid these pitfalls and ensure a smooth production process.

Here are some practical ways to reduce costs without compromising quality:

| Tip | Explanation |

|---|---|

| Use Standard Materials | Choose readily available materials like 6061 Aluminum |

| Simplify Geometry | Minimize complex cuts and deep cavities |

| Combine Parts | Where possible, combine multiple parts into a single component |

| Use Standard Tolerances | Only tighten tolerances where necessary |

| Optimize Surface Finishes | Choose cost-effective finishes unless critical |

Konlida offers a wide range of finishing options including anodizing, powder coating, electropolishing, and zinc plating.

The world of CNC Machining Parts is evolving rapidly. Here are the top trends:

Use of AI for automated machining path optimization

Increased demand for online CNC machining service with instant quoting

Sustainability focus: recyclable materials and energy-efficient processes

Micro-machining for miniaturized medical and electronics parts

Hybrid manufacturing (CNC + 3D printing)

Konlida stays ahead by integrating ERP systems, optimizing production lines for energy efficiency, and offering cutting-edge custom CNC machining service solutions.

Suzhou Konlida Precision Electronics stands out for:

18+ years of experience

88 core patents

21 surface treatment processes

87% repeat customer rate

Fast delivery with 1-5 days for prototypes, 7-15 days for small production runs

Whether you need CNC Machining Service Singapore or worldwide delivery, Konlida ensures top-notch quality and service.

A1: We accept PDF, DWG, STEP, IGS, and SolidWorks files for CNC Machining Parts drawing submissions.

A2: Aluminum is lightweight and corrosion-resistant, ideal for aerospace and automotive applications, while stainless steel offers superior strength and corrosion resistance, perfect for medical and food industries. Konlida’s Aluminum CNC Machining Service and Stainless Steel CNC Machining Services cover both needs.

A3: Yes! Konlida welcomes sample orders. Typically, samples are delivered within 7 days after design confirmation.

A4: We can achieve a minimum tolerance of 0.001mm for CNC Precision Machining Parts.

A5: For prototypes, lead time is 3 days. For production runs of 100-1,000 pieces, 7-15 days is standard.

A6: Absolutely. Our Online CNC Machining Service provides instant quotes within 2 hours after you upload your CNC Machining Parts drawing.

A7: Yes, we serve clients globally, including in Singapore, the US, Europe, and Japan. Our CNC Machining Service Singapore is especially popular among tech firms and startups.

A8: We commonly machine Aluminum, Stainless Steel, Titanium, Copper Alloy, and various engineering plastics like PEEK and ABS.

A9: Konlida specializes in medical devices, semiconductor equipment, automotive, robotics, optics, and new energy sectors.

A10: Yes. We manufacture a wide range of gears, including spur gears, helical gears, worm gears, bevel gears, timing pulleys, sprockets, and couplings.

Designing for CNC machining is both an art and a science. By understanding the capabilities and limitations of CNC technology, choosing the right materials, and working with an experienced CNC Machining Parts manufacturer like Suzhou Konlida Precision Electronics, you can achieve outstanding results.

Whether you need custom CNC machining service, online CNC machining service, or high-volume CNC Machining Services, Konlida stands ready to bring your designs to life with precision and efficiency.

Ready to start your next project?

Contact Konlida today for a free quote and expert consultation on your CNC Machining Parts drawing!

TEL: +86-512-66563293-8010

PHONE: +86-18068023605

E-MAIL: sales78@konlidacn.com

SKYPE: Shae Xie